Computer vision has become essential to building strong and stable manufacturing processes for operations of all sizes, and manufacturers across every industry are using the technology to boost the productivity and quality of their production lines. What was once reserved for only the largest manufacturers to invest time and money into building from scratch, harnessing the limitless capabilities of computer vision no longer requires a team of machine learning experts to integrate and deploy within your own facility.

If you’ve yet to incorporate computer vision into your manufacturing processes, start by selecting a portion of the process you’d like to improve. Often a manufacturer will start utilizing computer vision for one process, and then roll it out to incorporate many more use cases at their facility.

Real use cases of how manufacturers are currently using computer vision to transform their business:

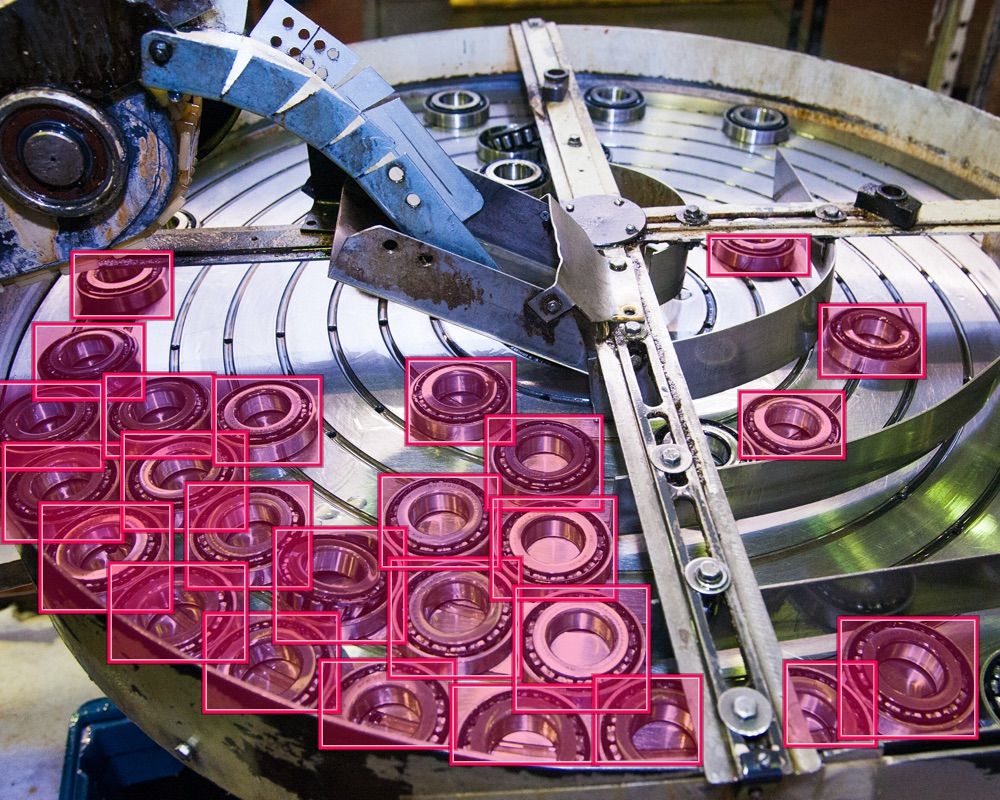

Predictive maintenance

Manufacturers are saying goodbye to the days of surprise breakdowns and halting production when equipment falters. Computer vision is helping to identify weakening systems in their assembly lines and alerting them to machinery that needs attention right away.

Defect detection

Computer vision can be trained to quickly and accurately identify defects in products and packages that would have resulted in costly recalls and materials lost. Manufacturers are training models to not only look for standard defects, but measuring for accurate dimensions, angles, and density—things that are harder to quickly assess with the naked eye.

Safety

Worker safety is paramount for running a successful manufacturing business. Computer vision can monitor for correct use of personal protective equipment being worn at all times, as well as verify that other safety procedures are being met. Manufacturers are using computer vision to protect their employees by providing the safest working environment they can.

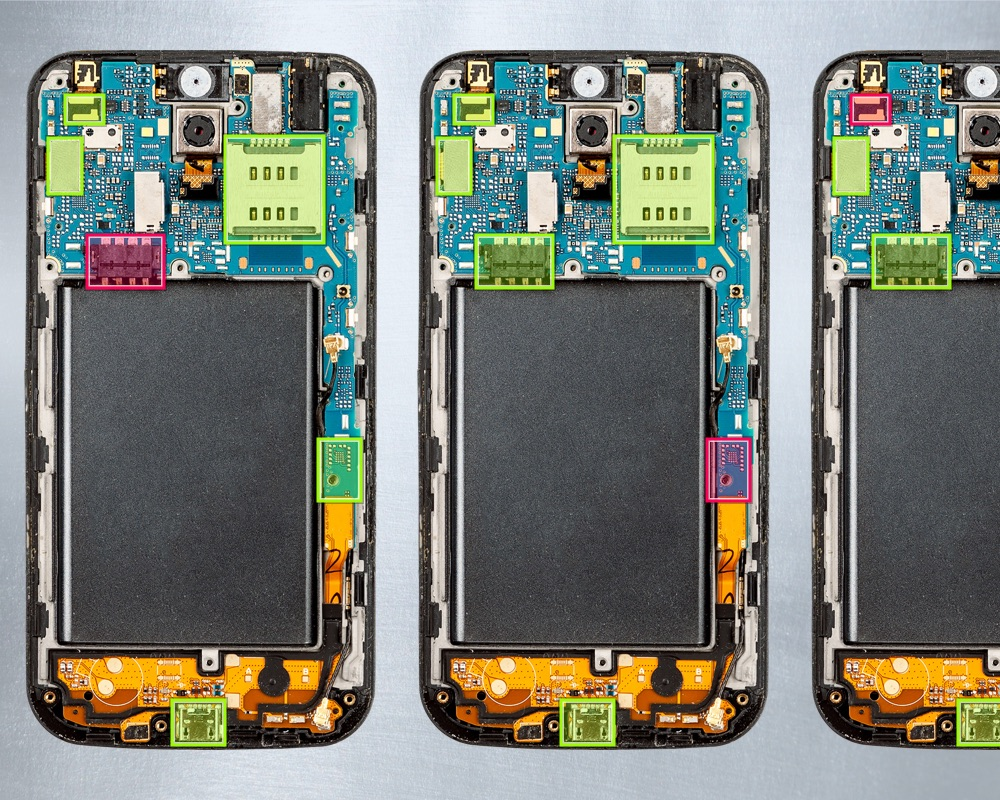

Assembling products and components

Computer vision can assist in assembling products accurately and reducing the amount of time it takes to complete a product build. When dealing with delicate items or parts that cannot be easily maneuvered manually, computer vision is providing superpowers to the machinery on assembly lines.

Reading barcodes and text

Computer vision can read barcodes and text to quickly and easily track components and packages at all stages of development, through a manufacturing facility to departure and beyond. Many manufacturers have begun incorporating barcode and text reading capabilities into their systems to better route products through the proper assembly lines.

If you haven’t started incorporating computer vision into your manufacturing processes, you can start today. Software companies like Roboflow give you the tools to integrate computer vision into your applications—no longer do you need to become a machine learning expert to take advantage of all computer vision has to offer.

Ready to get started? Contact sales or start testing Roboflow for free to see how you can use Roboflow for manufacturers.