Workplace safety is a critical concern for businesses. The most recent data from the U.S. Bureau of Labor Statistics reveals a staggering 2.6 million nonfatal injuries and illnesses recorded annually. On top of that, 82% of companies have faced at least one unplanned downtime incident over the past three years, leading to significant productivity losses.

These challenges highlight the need for solutions that not only protect workers, but also keep operations running smoothly. That's where AI and computer vision technology comes in. By proactively identifying hazards, monitoring equipment health, and ensuring compliance with safety protocols, workplace safety AI software is already helping facilities reduce risks, prevent costly incidents, and optimize operational efficiency.

Lets take a look at some of the key ways AI is being used today to improve workplace safety.

Vision AI for Workplace Safety

In industries such as automotive manufacturing, where the average company loses $22,000 per minute when the production line stops, ensuring workplace safety is a business necessity. Discover some of the most effective ways AI, particularly computer vision, is already being leveraged for real-time hazard detection, predictive maintenance, and employee monitoring.

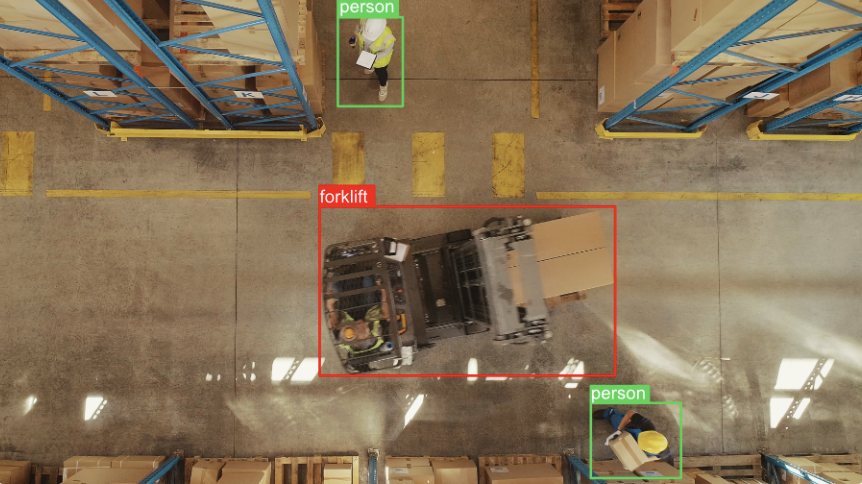

1. Traffic Flow Management in Warehouses or Factories

Computer vision can monitor the flow of employees and machinery to prevent collisions. To ensure employee safety, it's crucial to detect hazards and dangerous behavior proactively.

One industrial equipment manufacturer is introducing an AI-powered monitoring system that detects near vehicle-human collisions. Besides triggering alerts, the system records incidents in a database. That way, staff can potentially review trends and take proactive steps—like extra training —to prevent future collisions.

2. Fall Detection and Protection

Traditional fall detection systems use accelerometers and gyroscopes, worn on the body. Now computer vision systems can monitor workers’ movements and detect falls in real-time. Today's AI-enhanced systems can differentiate between a worker climbing down a ladder rapidly and an actual fall. Here's a case study of how computer vision can be used to detect falls on railways.

3. Personal Protective Equipment (PPE) Compliance

In a given year, approximately 65,000 workers wearing hard hats incur head injuries in the workplace, of which over one thousand ultimately die. Whether employees aren't being provided the proper gear by a specific supervisor, or workers ignore it because they find it uncomfortable, or they don't know it's needed in a particular area, AI-powered PPE detection can report how a facility is doing in terms of compliance. Vision AI can monitor workers to ensure they are wearing the required PPE, such as hard hats, gloves, and safety goggles - and send alerts to responsible parties when problems are identified.

4. Machine Safety Monitoring

AI can be used to ensure workers are maintaining safe distances from machines or hazardous equipment. In facilities where there are safety barriers, guardrails, or railings, computer vision can check if they are intact and properly positioned. Toyota Material Handling Japan has implemented AI-driven vision systems that help forklift operators avoid collisions by analyzing their surroundings and providing real-time hazard alerts.

5. Monitor Safety Signage

Vision AI can ensure that safety signs (such as fire exits, no-smoking zones, or caution labels - hard hat area, high voltage, and no entry) are properly placed and visible is essential areas.

6. Emergency Evacuation Assistance

During an emergency, computer vision can track evacuation progress to ensure all employees are accounted for.

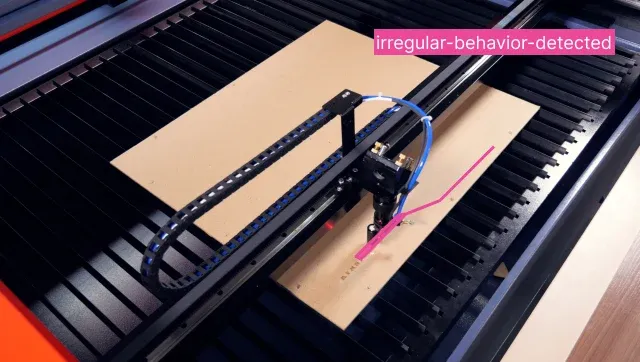

7. Hazard Detection and Defect Detection

Does your facility ever have wet floors, exposed wires, a hairline crack in a machine part, or equipment left in dangerous positions? Computer vision can help identify and flag all of these hazards in real time. AI can pick up even the smallest irregularities that the human eye might not catch. As just one example, some facilities even use AI to detect dust buildup in order to comply with federal health regulations.

8. Inspect Worksite Conditions

Computer vision can be used to inspect worksites regularly, identifying structural damage or signs of wear and tear that could lead to safety issues. For example, it could flag deteriorating scaffolding, preventing accidents before they happen.

9. Automate Reporting and Documentation

Computer vision can automate the process of documenting safety inspections, incidents, and compliance checks.

10. Track Downtime Causes

Factories typically lose between 5% and 20% of their manufacturing capacity due to equipment failure and other causes of downtime, according to the International Society of Automation. Computer vision can help identify the root causes of any unexpected production halts. For example, it can highlight if a malfunction in a particular step is consistently causing delays. It can also predict when equipment might fail.

Artificial Intelligence For Workplace Safety

Workplace safety is not just about preventing accidents—it's about creating an environment where operations run smoothly and employees remain protected. AI-powered computer vision offers a powerful solution to minimize risks, enhance operational efficiency, and prevent costly disruptions. Of course, vision AI solutions need to be safe, reliable, and secure.

Learn more about how Roboflow Enterprise can bring workplace safety solutions to your business.

Keep reading:

- An article on Implementing Quantity Inspection with Computer Vision

- An article on How to Detect Metal Defects with Computer Vision

- An article on Flaw Detection with Computer Vision

Cite this Post

Use the following entry to cite this post in your research:

Trevor Lynn. (Feb 11, 2025). Workplace Safety AI: Detect Hazards. Roboflow Blog: https://blog.roboflow.com/workplace-safety-ai/